Double Cut Power

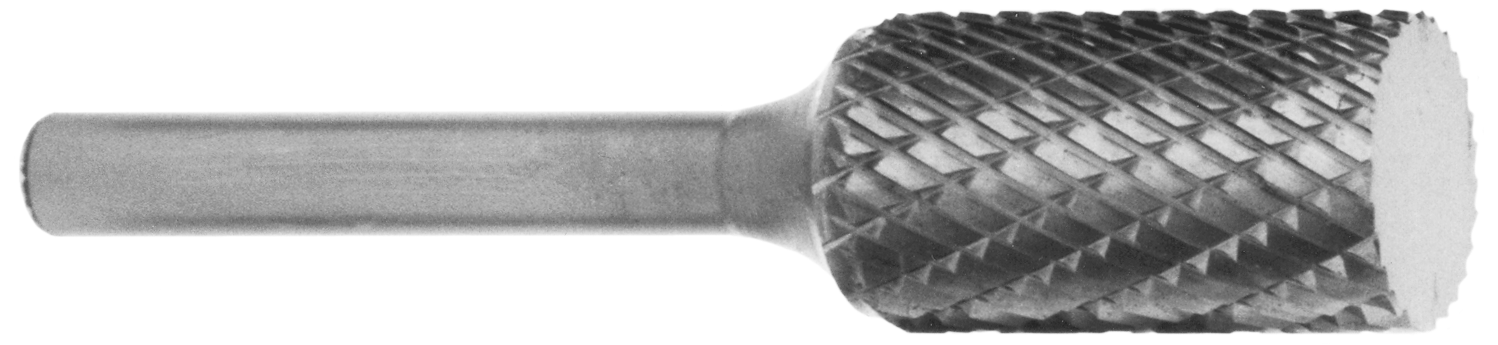

Carbo-Mills™ combine the hardness of tungsten carbide with an aggressive double-cut flute pattern for maximum material removal.

The double cut (also called cross-cut or diamond cut) pattern features two sets of flutes ground at opposing angles. This creates a series of diamond-shaped cutting teeth that break chips into small pieces, reducing loading and enabling faster cutting with a smoother finish than single-cut burs.

Double Cut Advantages

Faster Cutting

Cross-cut pattern removes material faster than single-cut while producing smaller chips that clear easily.

Smoother Finish

Multiple cutting edges produce a finer surface finish with less secondary finishing required.

Reduced Heat

Smaller chips dissipate heat better, keeping the workpiece and tool cooler during extended use.

Less Chatter

Diamond tooth pattern breaks up harmonics that cause chatter in single-cut tools.

Recommended Applications

- Die & Mold Work: Cavity finishing, parting line removal, EDM electrode preparation

- Weld Finishing: Grinding weld beads, preparing surfaces for re-welding

- Deburring: Removing heavy burrs from machined steel parts

- Porting: Engine head and intake manifold porting and polishing

- General Metalworking: Shaping, contouring, and finishing ferrous metals

Specifications

- Material: Tungsten Carbide

- Cut Pattern: Double Cut (DC)

- Shank: 1/4" standard

- Shapes: All standard shapes

- Hardness: Rockwell 90+

Regrind Service

Carbide tools can be resharpened multiple times. Save up to 70% on tool costs.

Learn More