Our Story

"We are the originators; we have been copied but not surpassed."

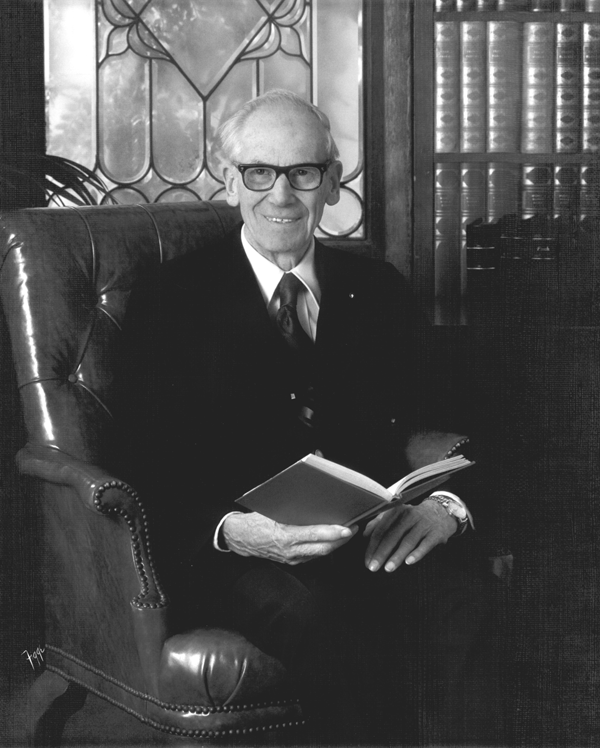

In 1931, Rollin M. Severance founded Severance Tool Industries with a revolutionary idea: a precision-ground rotary file that would outperform any existing deburring tool on the market. As a skilled toolmaker and engineer, Mr. Severance recognized that the stamped and poorly ground rotary files of the era were inadequate for the precision demands of modern manufacturing. His solution was the Midget Mill® - individually ground with exacting tolerances that set a new industry standard.

What started in a small Detroit workshop has grown into a recognized leader in precision cutting tools. Mr. Severance's commitment to quality and innovation established standards that we maintain in every tool we manufacture today. His philosophy was simple: "Build the best tool possible, and the customers will come." That philosophy has guided three generations of the Severance family.

Our Heritage of Innovation

From the beginning, Severance Tool Industries has been driven by the desire to solve manufacturing challenges. The original Midget Mill was developed to address the limitations of existing rotary files, which were either stamped or poorly ground. By individually grinding each flute to precise specifications, Mr. Severance created a tool that cut faster, lasted longer, and produced superior finishes.

This same innovative spirit led to the development of our Chatterless Countersink™ line, which uses a patented 6-flute design to eliminate the harmonics that cause chatter in traditional countersinks. Today, our engineering team continues to develop new solutions for modern manufacturing challenges.

Made in America

In 1939, Severance Tool Industries moved to its current home in Saginaw, Michigan. For over 80 years, our Saginaw facility has been the heart of our manufacturing operations. Every Severance tool is designed, engineered, and manufactured right here in Michigan by skilled American craftspeople.

We take pride in our American heritage and our commitment to domestic manufacturing. When you buy a Severance tool, you're supporting American jobs and American craftsmanship.

Rollin M. Severance

Founder, 1931

Company Facts

- Founded: 1931

- Founder: Rollin M. Severance

- Location: Saginaw, Michigan

- Products: 1,000+ SKUs

- Trademark: Midget Mill®

Our Promise

Every Severance tool is manufactured to the highest standards. If you're not satisfied with a product, we'll make it right.